Peter Brown has contributed to the growth and prestige of Canada’s mining industry by helping many resource entrepreneurs and emerging companies gain access to venture capital that enabled them to acquire and explore promising mineral prospects or develop and operate new mines. He has been a dynamic force in the Canadian capital markets since 1968, when he joined Ted Turton in purchasing control of a small Vancouver brokerage firm for $23,000. By focusing on the small to mid-sized resource and junior industrial firms, long ignored by senior investment firms, he transformed Canaccord Capital Inc. (since renamed Cannacord Financial Inc.) into the largest independent investment dealer in Canada, with successful operations in Europe and the United States.

Peter Brown has contributed to the growth and prestige of Canada’s mining industry by helping many resource entrepreneurs and emerging companies gain access to venture capital that enabled them to acquire and explore promising mineral prospects or develop and operate new mines. He has been a dynamic force in the Canadian capital markets since 1968, when he joined Ted Turton in purchasing control of a small Vancouver brokerage firm for $23,000. By focusing on the small to mid-sized resource and junior industrial firms, long ignored by senior investment firms, he transformed Canaccord Capital Inc. (since renamed Cannacord Financial Inc.) into the largest independent investment dealer in Canada, with successful operations in Europe and the United States.

A third generation British Columbian, Brown began his career in the early 1960s with Greenshields Inc. in Toronto and Montreal. He returned to Vancouver in 1967 just as scandals in both the Toronto and Montreal markets greatly reduced the capital available for small and emerging companies, and in particular the risk capital desperately needed for mineral exploration and development.

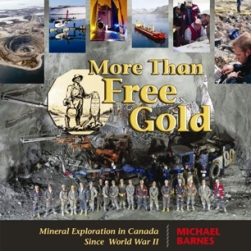

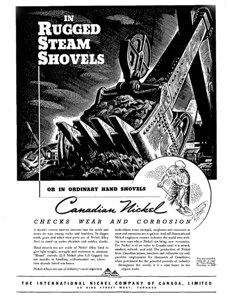

Prosperity, modernity, pioneer color and a relief problem

Prosperity, modernity, pioneer color and a relief problem